Ariginal Lighting’s Solder-Free Feature:

Pioneering a New Era in Profile Lighting

Shenzhen Ariginal Lighting Co., LTD. continues to redefine the lighting industry with its groundbreaking innovations, and the latest addition to its arsenal is the solder-free feature, particularly tailored for profile lights. This revolutionary technology eliminates the need for soldering, simplifying installation, enhancing flexibility, and ensuring a seamless user experience. By addressing the complexities of traditional lighting assembly, Ariginal’s solder-free feature stands as a testament to the company’s commitment to innovation, quality, and customer empowerment, perfectly aligning with its mission to brighten homes worldwide with creative, unique solutions.

Understanding the Solder-Free Feature

The solder-free feature refers to the ability to connect and install profile lights—linear fixtures made of aluminum profiles housing LED strip lights, wires, and connectors—without the traditional process of soldering. Soldering, which involves melting metal to join electrical components, has long been a standard practice in lighting installation, requiring skill, time, and specialized tools. Ariginal Lighting has turned this convention on its head, enabling users to assemble and customize profile lights effortlessly. This innovation is made possible by three critical preconditions, each meticulously engineered to ensure compatibility and performance.

The Three Preconditions of the Solder-Free Feature

1. Freely Cuttable Aluminum Profile:

- The foundation of the solder-free feature lies in Ariginal’s free-cut technology, which allows the aluminum profile to be cut to any length with precision, anywhere along its structure, without adhering to fixed increments. This flexibility ensures that the profile can be tailored to fit any space—whether it’s an irregular kitchen countertop or a curved living room accent—without compromising structural integrity. The freely cuttable nature eliminates the need for pre-soldered segments, paving the way for a modular assembly process.

2. Solder-Free LED Strip Light:

- Inside the aluminum profile, Ariginal incorporates a specially designed solder-free LED strip light. Unlike traditional strips with dotted solder pads at specific intervals, these strips feature continuous solder pads along both the left and right sides. This continuous design ensures uninterrupted electrical conductivity, allowing the strip to be cut and connected at any point without the need for soldering. This innovation, developed by Ariginal’s team of 20 highly educated engineers, supports the company’s vision of a one-minute setup, making installation accessible to all.

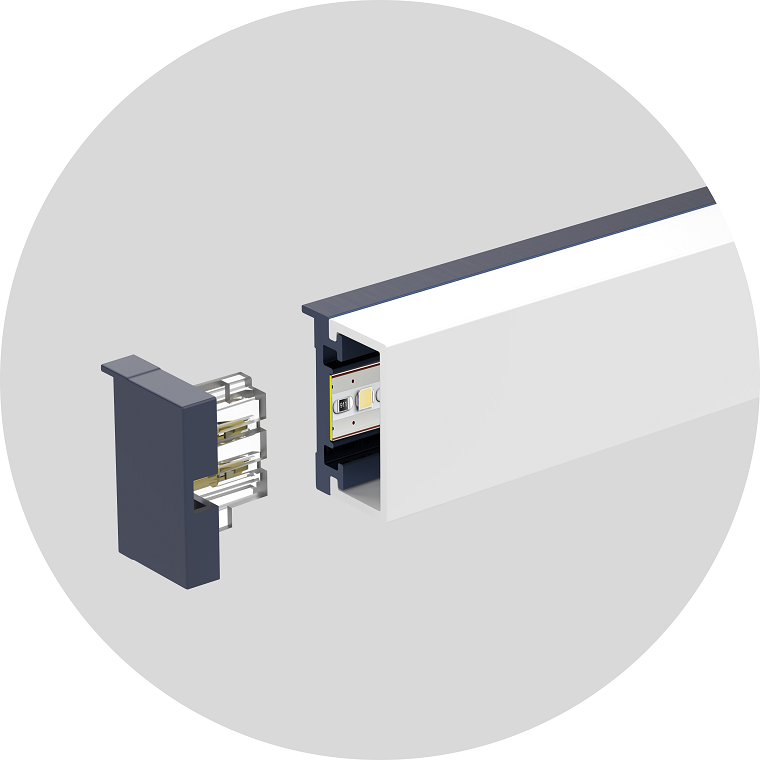

3. Specialized Compatible Connector:

- The final piece of the puzzle is a custom-designed connector that seamlessly integrates with the aluminum profile’s shape and the LED strip’s continuous solder pads. This connector features metal contacts with an exact width matching the strip’s pads, ensuring a secure and reliable electrical connection. Compatible with Ariginal’s plug-and-play system, the connector eliminates the need for soldering tools, enabling users to simply plug the components together. This design, paired with high-quality materials, upholds Ariginal’s rigorous quality standards, including a 24-hour aging test and a 100% QC pass rate.

How the Solder-Free Feature Works

The solder-free feature transforms the installation process into a straightforward task. Users begin by cutting the aluminum profile to the desired length using the free-cut method. The solder-free LED strip, pre-inserted into the profile, is then aligned, and the specialized connector is plugged in, establishing an instant connection. This process is supported by Ariginal’s use of DuPont connectors for DC connections and C7 plugs for AC connections, ensuring compatibility across the system. The result is a profile light that can be installed, disconnected for maintenance, or reconfigured in minutes, all without the heat, mess, or skill required for soldering.

Benefits of the Solder-Free Feature

- Simplified Installation: By removing the need for soldering, the feature makes setup accessible to DIY enthusiasts and professionals alike, reducing the learning curve and setup time to a fraction of traditional methods.

- Enhanced Flexibility: The combination of free-cut profiles and solder-free strips allows for precise customization, adapting to any space or design vision with ease.

- Efficient Maintenance: Components can be disconnected and replaced without soldering, simplifying repairs and upgrades, and minimizing downtime.

- Safety and Quality: The absence of soldering reduces the risk of overheating or electrical faults, while Ariginal’s global certifications (UL, CE, CCC, ROHS) and a 5-year quality guarantee ensure reliability.

- Sustainability: Eliminating soldering reduces waste and the use of hazardous materials, aligning with Ariginal’s eco-conscious approach.

The Ariginal Advantage

Developed by a team with expertise in hardware, software, and industrial design, the solder-free feature reflects Ariginal’s “Innovation is Our Soul” philosophy. Manufactured in state-of-the-art factories spanning 80,000 square meters across Huizhou, Zhongshan, and Dongguan, these profile lights benefit from over 20 years of partner factory experience. With over 100 patents and collaborations with global brands like Hettich and Richelieu Hardware, Ariginal ensures its products meet the highest standards. The feature integrates seamlessly with the company’s plug-and-play and modular systems, further enhancing installation speed and ease.

Real-World Impact

Imagine a designer outfitting a modern kitchen with under-cabinet profile lights. Using Ariginal’s solder-free system, they cut the aluminum profile to fit the exact countertop length, plug in the solder-free LED strip with the compatible connector, and power it up—all within minutes. If a section needs adjustment or repair, the modular design allows for quick swaps, supported by Ariginal’s 1-hour money-back guarantee and 5-minute inquiry response. This efficiency, backed by a $16 million annual turnover and 180 dedicated employees, positions Ariginal as a leader in furniture lighting.

Conclusion

Ariginal Lighting’s solder-free feature revolutionizes profile lighting by eliminating the need for soldering, made possible by freely cuttable aluminum profiles, continuous solder-pad LED strips, and specialized connectors. This innovation simplifies installation, enhances flexibility, and upholds the highest standards of quality and safety, true to Ariginal’s name. As the company continues to brighten homes worldwide with creative, unique solutions, the solder-free feature stands as a beacon of progress, transforming the way we design and maintain lighting systems with unmatched ease and efficiency.